Hardware, Software and Electronics for Ink Management Systems

Management Systems for Inks and Fluids

GIS provides a range of components for Ink Management Systems (IMS), including standalone electronics and software for ink supply system control, as well as inkjet header tanks, system controls for pressure, filtration, heating and degassing, plus system design consultancy.

The GIS IMS components can be used with most industrial inkjet printheads and ink types, including aqueous, UV curable and functional fluids – subject to materials compatibility tests.

This modular solution, combined with design consultancy, allows machine builders and OEMs to integrate customised solutions according to their commercial and technical needs.

GIS IMS components can be integrated with 3rd party printhead drive electronics – this is a standalone product offering.

Ink Management Systems Product Catalogue

Click the link below to view/download our product catalogue:

GIS Software and Electronics for IMS

We collaborate with customers to design and configure a system tailored to your specific requirements. Furthermore, we design custom parts if required and we adopt a ‘building block’ approach.

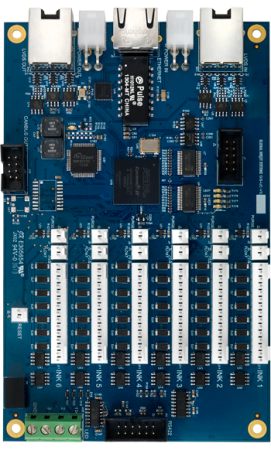

Each Ethernet networked GIS ink control board (ISC-IMB-I6) can control from 1 to 6 fluids/inks independently. Two or more boards can be connected for systems that require 7 – 12 fluids/inks and beyond.

System Controls

- Up to six different fluids per control card

- Multiple control cards for more than 6 fluids

- Independent ink purge

- Overnight and weekend switch off (automatic on power off) – offers limited head drip

- Long-term switch-off (manual)

- Non circulating (end shooter) & recirculating capable

- Recirculating modes: High Flow/Low Flow/Controlled Flow

- High pressure purge

- Low pressure purge

System Controls

- Easy printhead change (system does not require draining)

- Fault detection

- In-line and header tank heater options

- Ink degasser

- Control cards can be daisy chained for more fluids

- Single cable can bus link to header tanks (1 per colour)

- Header tanks can be daisy chained together

- Runs from 24V supply

- Ethernet cable to PC

Header Tanks

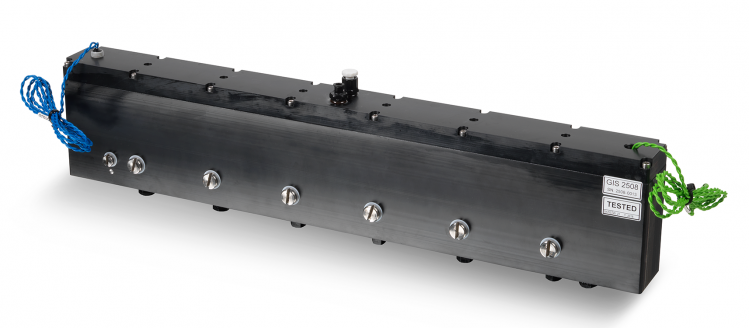

GIS offers a range of standard and customised header tank designs. Each standard tank can support up to two printheads per tank. Larger header tanks are available for wider printhead arrays. GIS header tanks are also designed to consider different flow modes, space restrictions and ink capacity requirements for different applications and printer sizes.

Header Tank Features and Controls

- Integral overflow protection

- Integral pressure sensor(s)

- Integral control valves for switching between modes and auto switch off

- Manual valve per head (for easy head replacement) and long term switch off

- Swagelok stainless steel ink tube connectors to printhead

- Luer-lok connectors for ink in/out

- Careful design to minimise pigment traps and to encourage air bubble release

- Sized to feed number of printheads per ink

PEEK Header Tank

The PEEK Header Tank from GIS offers extended materials deposition compatibility.

It is specifically designed to offer high resistance to aggressive fluids, incorporating an FFKM gasket. As with all GIS header tanks, the PEEK version is available in different sizes according to each system’s requirements.

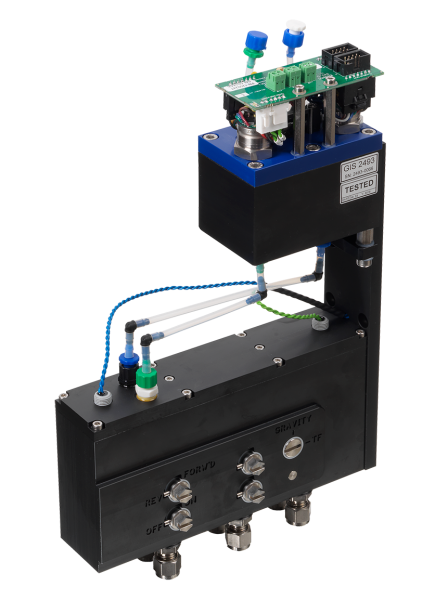

Purge Control

Low pressure purge

- Used for most printhead types

- For end shooter and recirculating systems

High pressure purge

- Pressure built up to circa 1 bar before releasing to header tanks

- Optional support for external high pressure source

The GIS IDS Components can be used with printheads with different ink flow modes:

- No flow for end shooter printheads

- Low flow recirculating end shooter printheads using inks that can benefit from recirculation

- Controlled, adjustable flow recirculating

Download our product catalogue

Click the link below to view/download our product catalogue: